In 2023, the textile and garment industry targets export revenue for the whole year 2023 of 43.5 billion USD. According to many experts, in the current context when the export picture continues to be unfavorable, the target may be difficult to achieve. However, it is important towards the long-term goal for Vietnam's textile and garment industry today to "green" production, not only contributing to reducing emissions but also helping businesses improve competitiveness, especially in major export markets. Industry and Trade Magazine discussed this content with Mr. Vu Duc Giang - Chairman of the Vietnam Textile and Garment Association.

Reporter: At the end of 2022, the Government approved the Vietnam Textile and Garment and Footwear Industry Development Strategy to 2030, vision to 2035 (Strategy), it is known that Vitas has also recently issued a draft on the implementation of the Textile and Garment Industry development strategy according to Decision 1643/QĐ TTg dated 29/12/2022, so please tell us the key contents that this program aims at What is it?

Mr. Vu Duc Giang: At the end of 2022, the approved strategy with specific targets is recognized which will create a great motivation for the textile and garment industry to increase investment attraction, expand production, make good use of existing advantages, and boost exports. However, in fact, about 5 years ago, the Vietnam Textile and Garment Association (VITAS) launched a sustainable development model consisting of 3 pillars: Profit, People (employees), and Planet (environment).

Specifically, profit is the target of all enterprises. The solution VITAS offers for this pillar is to proactively source raw materials, develop brands, manage risks, reduce costs, grow business, and be profitable. The Association also identifies employees as the most valuable asset of enterprises. Therefore, it is necessary to train workers to meet their needs; improve working conditions, and income; create harmonious industrial relations.

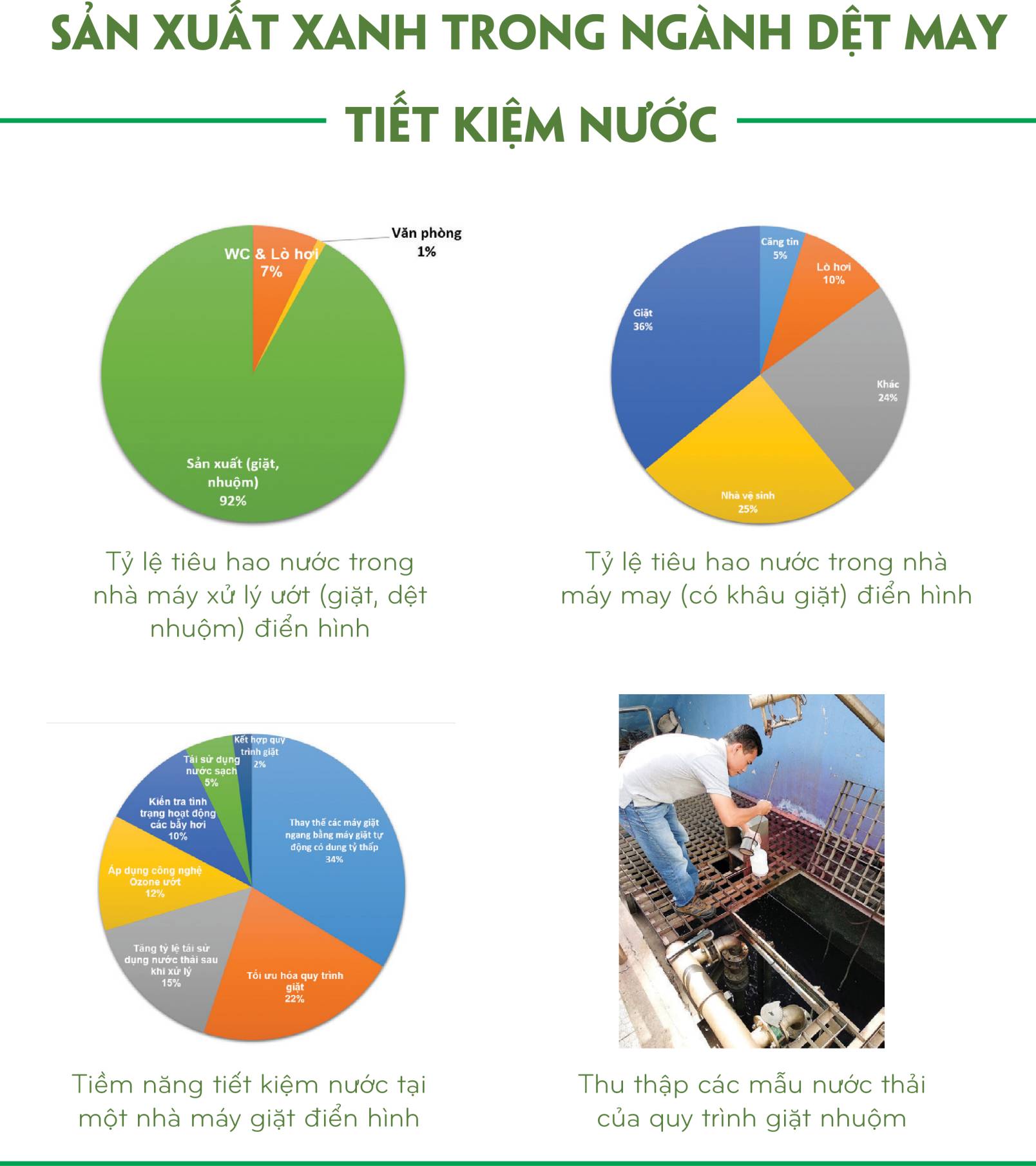

For environmental issues, this is an irreversible trend, so businesses need to focus on reducing waste; water treatment and reuse; use of renewable energy; recycling, reuse, and product traceability. The Sustainable Development Program implementing the Association's Strategy focuses on 3 main issues including promoting the formation of textile and garment industrial parks to proactively supply NPL; fashion design development, brand development; focus on training textile and garment human resources"

In order to achieve the set strategic goals, VITAS has proposed to the Ministry of Industry and Trade the Program to support the sustainable development of the textile and garment industry according to the Strategy to 2030 with a proposed budget of VND 435.6 billion, including 8 items:

1) Survey the current status of Vietnam's textile and garment industry; 2) Research, development, application, transfer, and innovation of technologies for the production of green and renewable materials; 3) Support projects on green transformation, wastewater treatment, chemicals, renewable energy, etc.; 4) Support in fashion design, ecological design, brand building, and promotion; 5) Cooperate with foreign partners in training human resources for NPL production, especially textile, dyeing, and prototyping design; 6) Training for enterprises on production management, value chain management, and customers; 7) Support the application of new technologies to improve efficiency, productivity, and quality; 8) Support capacity building for institutes, universities, colleges, and vocational training.

Reporter:Greening is an important content that the Textile and Garment Industry will have to focus on, which helps enterprises in the industry improve their competitive position, contributing to the common goals of the country. So how specifically is this content mentioned in the draft Sustainable Development Program of VITAS, sir?

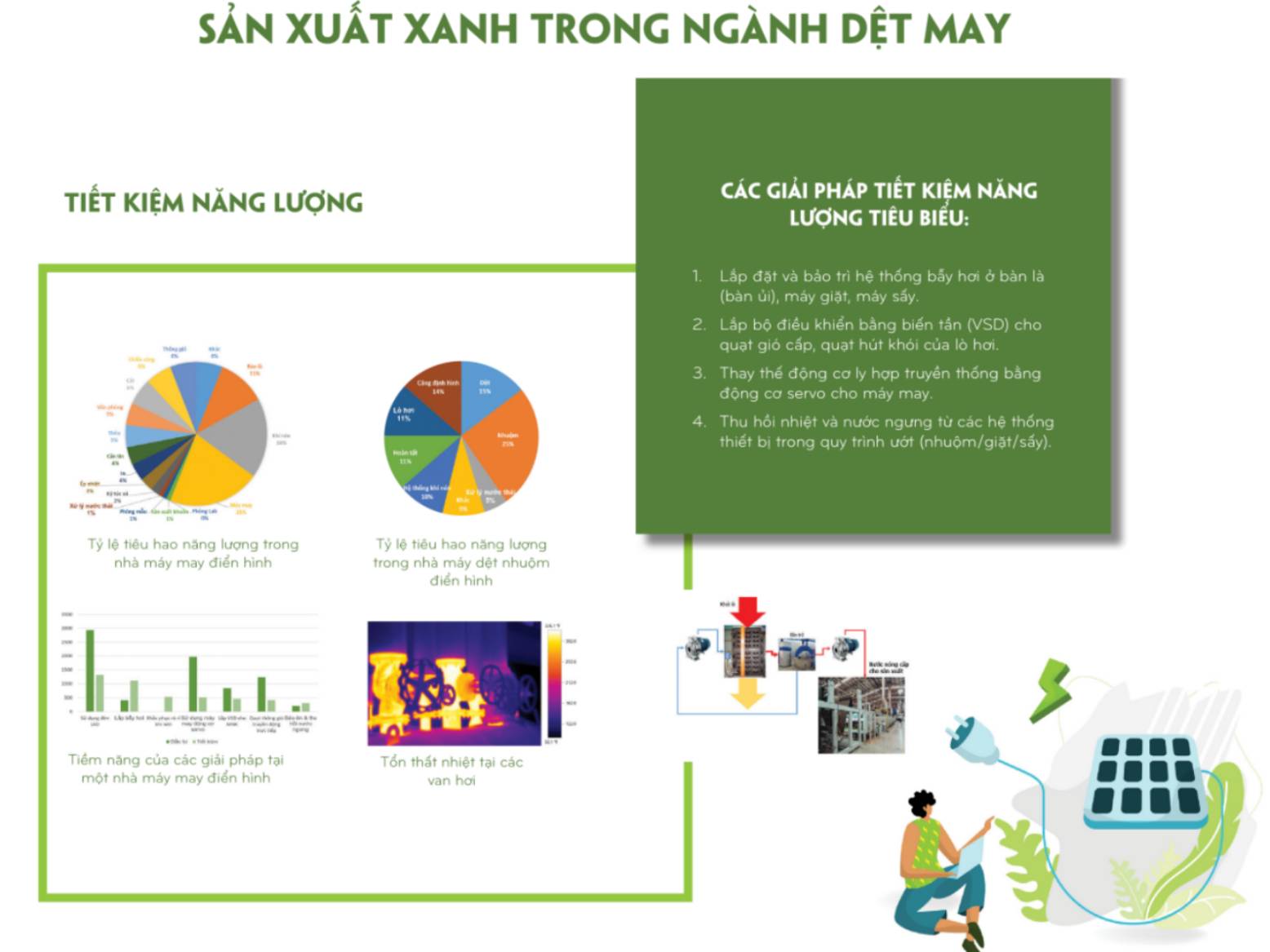

Energy Saving Solutions for Greening in Textiles

Mr. Vu Duc Giang: Since 2017, VITAS has established the Sustainable Development Committee and implemented many activities and had spillover impacts on industry enterprises. In the recent draft Sustainable Development Program, VITAS included 2 specific tasks to support the greening process of enterprises, including Research and development, application of transfer and innovation of technology to produce green materials, renewable materials, and support green transformation projects, wastewater treatment, chemicals, renewable energy ...

Accordingly, conducting research on development trends in the global textile and garment chain, and trends in technological innovation for sustainable development; formulating and announcing national technical standards and regulations on green raw materials in conformity with international standards; Support research and application of technology transfer and innovation in the production of green and renewable materials; Survey the needs of enterprises on green transformation; Support research and application of advanced technologies in the field of wastewater treatment, chemicals, renewable energy; Support the application of research results at enterprises in need.

Images of Greening in the Textile and Garment Industry

Reporter: From quite early on, many enterprises in the industry actively implemented activities to gradually transform "greening" production and improve competitiveness. Can you tell us a little bit about this transition?

Mr. Vu Duc Giang: The requirement of sustainability and competitiveness has pushed Vietnamese textile and garment enterprises to green transformation. In fact, many businesses have oriented sustainable development many years ago. Specifically, Thanh Cong Textile - Investment - Trading Joint Stock Company (TCM) has invested in research and business development (R&D), creating new products with specific features, being environmentally friendly, and meeting customers’ increasing needs. Or Bao Minh Textile factory is invested in much high-tech equipment, deploying Oracle ERP solution integrated with Setex operating systems, Toyota brings efficiency and accuracy, and synchronization to production activities.

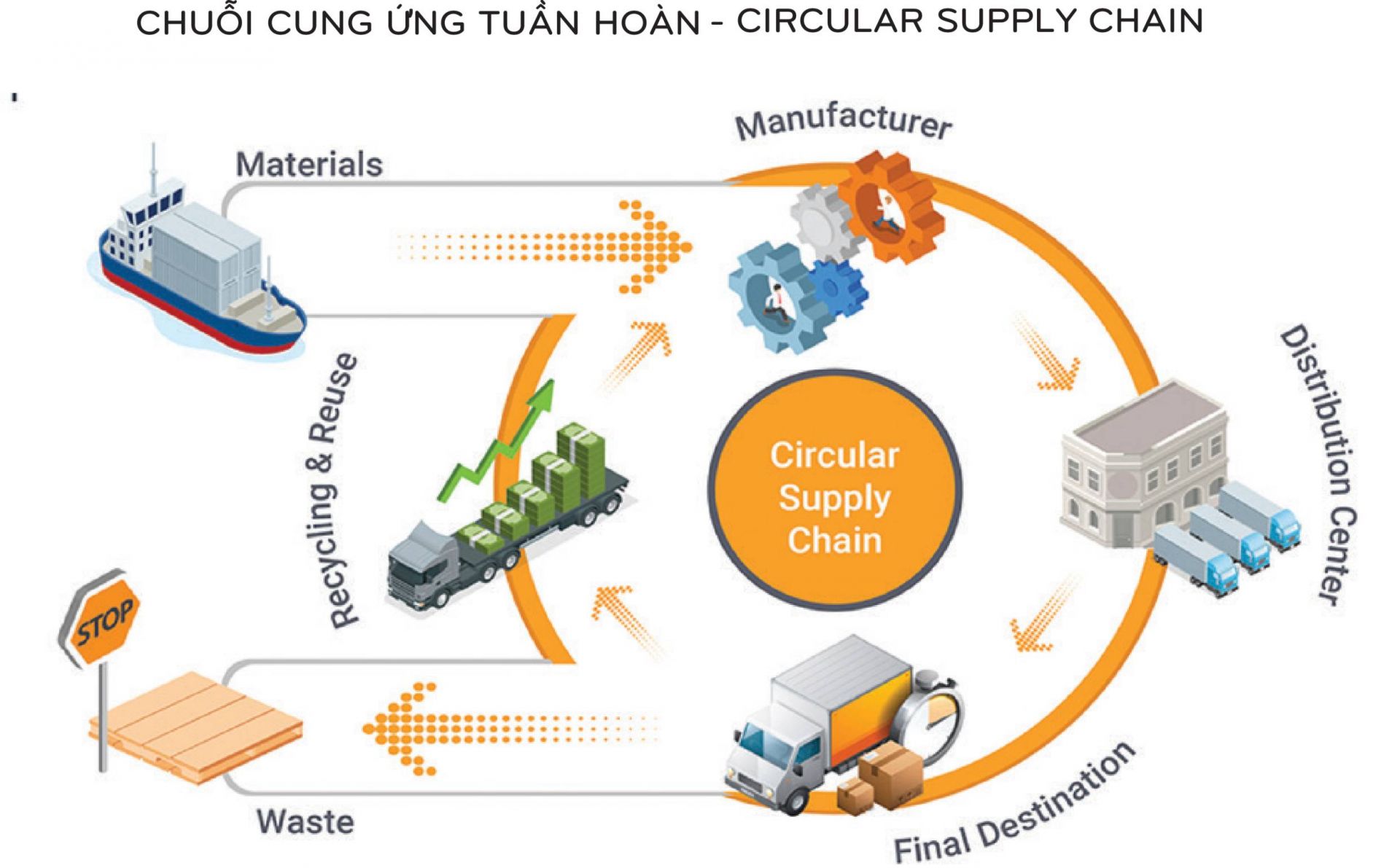

Many businesses have converted to rooftop solar power systems, replacing coal-fired boilers, and burning oil with electric boilers, not only applying technology in production but also in corporate governance.

Circular supply chain model in the garment industry

Reporter: Many businesses have also encountered many difficulties in greening production. So in your opinion, what are the bottlenecks that make textile and garment enterprises have not accelerated green transformation? and proposed proposals to remove knots?

Mr. Vu Duc Giang: There are three issues that are said to be difficulties and barriers for businesses in the greening process. Firstly, not all businesses have the right awareness of this issue to best prepare for greening.

The second is the financial issue because related to greening, the need for capital is huge and not all businesses have enough financial resources to implement this problem, especially since 80% of textile and garment enterprises are small and medium enterprises.

Third, it is human resources, because the issue of training human resources to meet greening as well as meet the requirements of the Fourth Industrial Revolution is very important and necessary but businesses are still weak.

In the development of the textile and garment industry, the role of enterprises is still the most important. But if you only rely on the enterprises themselves, it will be difficult to need the support of State management agencies. In particular, the planning orientation of green industrial parks with wastewater treatment systems meeting international standards is very important. Textile and garment enterprises in industrial zones (including DM and mixed IPs) include 1,210 enterprises with a total of 610,400 employees, accounting for about 1/3 of the textile and garment labor force nationwide.

Currently, textile and garment have many specialized industrial parks, most of the industrial parks with wastewater treatment systems have attracted investment to fill such as DM Pho Noi B, Bao Minh, Phuc Khanh, Nguyen Duc Canh, Binh An, Nhon Trach. Some industrial zones such as Rang Dong, Phong Dien ... The occupancy rate is still low, due to many reasons, including wastewater treatment.

The development strategy also only mentions focusing on building a number of industrial parks and complexes specialized in Textile and Garment and Leather and Footwear (including chains, fibers, textile dyeing, fabric finishing, and tanning); adopting policies to prioritize projects with large capacity from reputable investors, using advanced and modern technologies, having synchronous and closed production processes to ensure compliance with environmental regulations; Orientation in the North (Nam Dinh, Hung Yen, Thai Binh,...); the Central (Thanh Hoa, Nghe An, Thua Thien Hue, Quang Ngai, Binh Dinh,...) and the South (Binh Phuoc, Tay Ninh, Long An...)

Reporter: Technology transformation with textile and garment enterprises is also an important content in green transformation. Could you please tell us if businesses of the industry face any difficulties and propose recommendations to remove difficulties?

Mr. Vu Duc Giang: Digital transformation and technology transformation is an inevitable requirements of the textile and garment industry. However, the biggest barrier businesses face in the process of digital transformation and digital technology application is the high cost of investment in technology applications and automation equipment. In addition, the low labor level makes the process of operating machines and applying technology has not met expectations. As a key export sector, it is necessary to have specific support policies for textile and garment enterprises, from lending interest rates to loan access mechanisms. In particular, the Government should develop and promulgate mechanisms and policies to encourage the import of source technologies, high technologies, and clean technologies; encourage enterprises to invest in new machinery, equipment, and technologies.

Reporter: Thank you very much!

Source: Tapchicongthuong.vn

Aurora Textile Industrial Park - Aurora IP

Nam Đinh Office: Lot HC3, N2 Road, Rang Dong Textile Industrial Park, Rang Dong Town, Nghia Hung District, Nam Dinh Province, Vietnam

Southern Regional Office: 2nd floor, 261H Nguyen Van Troi st.,Ward 10, Phu Nhuan dist.,HCMC, Vietnam

North Regional Office: HCO Building 5th floor, 44B Ly Thuong Kiet st., Hoan Kiem dist., Hanoi, Vietnam

Tel: (0228) 8856 886

Email: [email protected] - [email protected]

Fanpage: www.facebook.com/RANGDONG.AURORAIP